※ Please install a pressure-reducing valve if the water pressure exceeds 60 PSI.

| Model No. | Fitting Type | Weight (incl. tank) | Cu'ft |

| ROQ-3815(H) | JACO | 9 kgs | 1.1 cu.ft |

Cartridges:

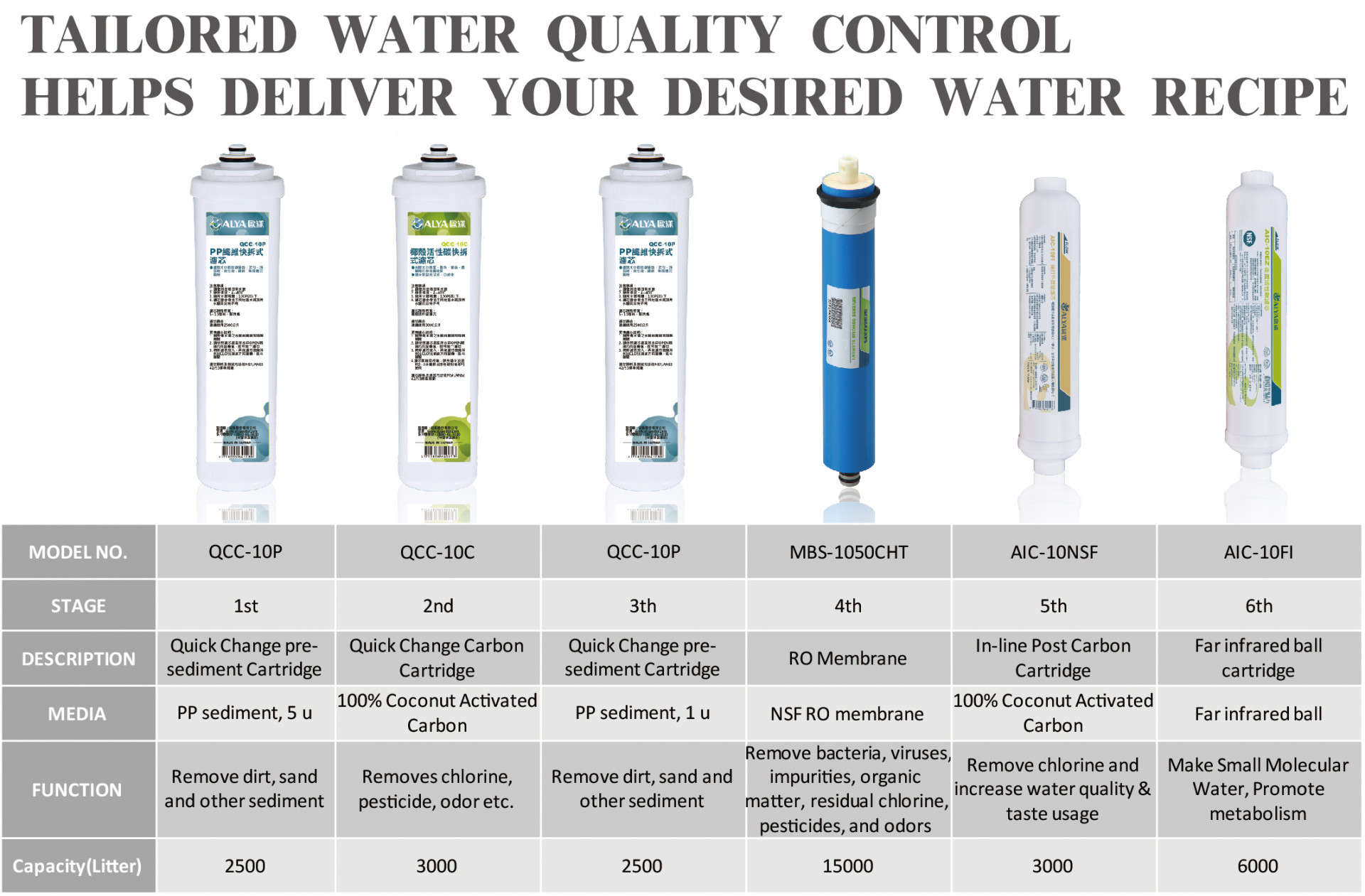

| Stage | Model No. | Media | Function |

| 1st | QCC-10P | PP sediment, 5 µ | Remove dirt, sand and other sediment |

| 2nd | QCC-10C | GRANULAR ACTIVATED CARBON (GAC) | Reduce chlorine, taste & odor |

| 3rd | QCC-10P | PP sediment, 1 µ | Remove dirt, sand and other sediment |

| 4th | MBS-1050 | 50 GPD membrane, NSF | Remove virus, bacteria, heavy metal, etc. |

| 5th | AIC-10 | Coconut GAC, NSF | Have better tasting of water |

Assembly

| Spare parts | Model No. | Spec. |

| Membrane housing | HM-256 | White, 1/8"NPTx1/8"NPT |

| Storage tank | TANK-4MW | 4 gallon, metal white |

| Shut-off valve | SD-11024/22024 | White, 1/4" Jaco type |

| Drinking faucet | ZWDF-1002 | Quarter-turned spout, 3" shank, lead-free |

| Flow restrictor | FRB-450 | bead type, 450ml, green color |

| PUMP | PUMP-5024DC | 50 GPD, 24VDC |

| VOLTAGE | TRAN-22024DC | 100~240/24VDC,1.2A, ROUND PLUG |

Accessories

| Spare parts | Model No. | Spec. |

| Water feed adaptor | BV-1414L | 11/4" ball valve with 1/2"MIPx1/2"FIP water feed fitting |

| PE tube | PE-14W-NSF | 1/4" tube, white, NSF |

| Ball valve for tank | BV-8P | Plastic, 1/4" Jaco |

Package

| Carton box type | Corrugated box |

| Package | System and tank are packed seperated |

Containers

| Container Dimension | Cu'ft | Quantity |

| 20ft | 1,172 CU'FT | 380PCS |

| 40ft | 2,385 CU'FT | 755PCS |

| 40'HQ | 2,690 CU'FT | 880PCS |

Others

■ Quick-fitting type system is optional

■ Manual flush valve is optional

■ Pressure gauge is optional

| Taiwan Excellence Award 2016 ROQ-3815(H) | ||

|

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.